Risk Based Process Safety Management Program

Risk-Based Process Safety (RBPS) Program

Elevate Your Safety Standards with Risk-Based Process Safety (RBPS) Training

At CLIDE, we are committed to helping businesses manage process safety risks in a structured, proactive manner. Our Risk-Based Process Safety (RBPS) Training Program is designed to equip your team with the tools and knowledge necessary to prevent major accidents, protect assets, and ensure operational continuity.

In dustry Specific Solution

As one size doesn’t fit all, hold true for our RBPSM solution as we are the best know for our customized solution offerings as per the organization and industry type. We just don’t help you in reducing the incidents but also help in shaping workforce behavior, mindset as everything is linked to process safety culture.

What Is Risk-Based Process Safety (RBPS)?

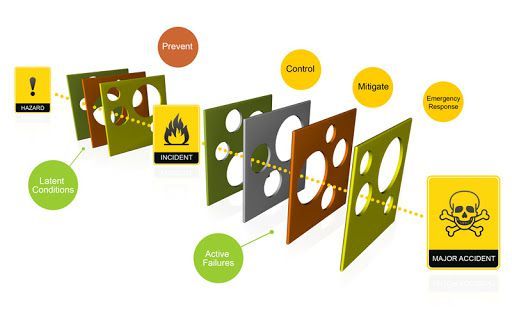

Risk-Based Process Safety (RBPS) is an advanced approach to process safety management that focuses on identifying, assessing, and mitigating risks associated with complex industrial processes. RBPS goes beyond compliance by promoting a culture of continuous risk management, where organizations focus on preventing major hazards and incidents rather than just responding to them.

This training provides participants with:

- A comprehensive understanding of RBPS principles

- Tools to assess and prioritize process risks

- Strategies for implementing long-term safety improvements

Build Proactive Safety Culture

Reduced Workplace Accidents

Enhanced Employee Engagement

Sustained Safety Improvements

Reduced Risk of Major Accidents

Minimize the likelihood of catastrophic events by identifying and mitigating process risks early.

Enhanced Operational Reliability

Improve process efficiency and minimize downtime by addressing risks that impact operational continuity.

Regulatory Compliance

Ensure your organization is in compliance with industry regulations and standards, such as OSHA's PSM (Process Safety Management) and EPA’s RMP (Risk Management Program).

Strengthened Leadership

Equip your leadership team with the tools to lead by example and support a culture of safety.

Improved Safety Culture

Foster a culture where safety is a core value, empowering employees to take responsibility for identifying and mitigating risks.

Long-Term Cost Savings

Fosters trust, loyalty, and commitment among employees, leading to greater productivity and success

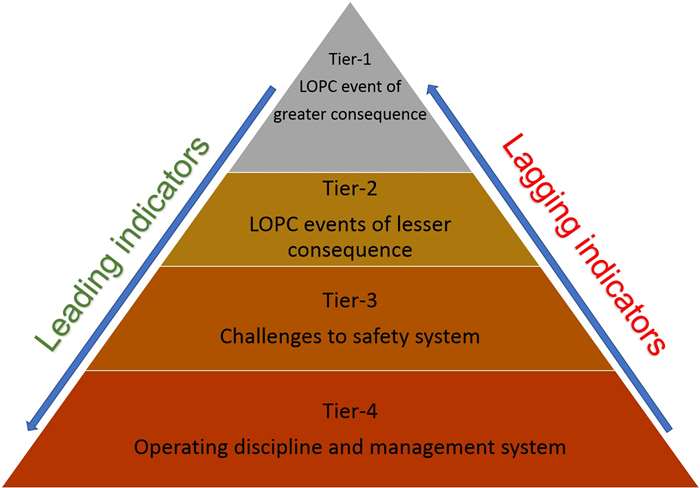

Process Safety KPIs

KPIs form the primary means of management feedback on the control of process safety risk and form part of the business assurance model for safe operations. Here is how companies can develop a safety improvement strategy.

Learn how to develop your KPIs.

Why Choose Our RBPS Training Program?

Our RBPSM Program is designed to meet the specific needs of industries handling hazardous materials and processes. By integrating best practices with practical applications, our program offers a unique approach to safety management. Here’s why organizations trust us:

Industry Customization

Tailored to meet the unique challenges of industries such as chemical, oil and gas, pharmaceuticals, and manufacturing.

Expert Trainers

Our team of trainers includes seasoned industry professionals with years of experience in process safety management and risk assessment.

Comprehensive Course

Covering all elements of the RBPS framework, from process hazard analysis to management of change.

Real-World Case Studies

We use examples from real-life incidents to demonstrate key concepts and teach critical problem-solving skills.

Our Approach

The RBPSM Program is designed around three core pillars that are proven to drive sustained personal and organizational performance:

Leadership

Build the ability in yourself and your team to persevere and thrive when faced with complex challenges. Understand how to foster a climate that encourages safe behaviour and lead by example.

Strategy

Immerse in decision making and how it impact the workplace safety and the organization. Expand your understanding of how data analytics can be leveraged for business impact.

Execution

Explore how agile approaches and design thinking can make your team more innovative and more safety-focused. Leverage the creativity of all your team members through optimized approaches to collaboration.

Process Safety Strategy

PSM related incident has increased in the past and organisation need a proven approach to prevent them. Analysing the past incidents we have identified four principles that will help organisations to develop a new incident reduction strategy.

The developing strategy needs good insights.

Learn more

CLIDE Leadership Insights

By number till now Testimonials

704

Training conducted

76

Top companies is our client

20

Program conducted in each company

Contact us to know more about our RBPSM Training program.

Join us and make your company a safer place.

Key RBPS Program Components

Our RBPSM Training Program is built around the four pillars of process safety as outlined by the Center for Chemical Process Safety (CCPS), ensuring comprehensive coverage of all aspects of process risk management.

Commitment to Process Safety

Explore the organizational commitment needed for a strong safety culture. This module covers leadership involvement, accountability, and the development of a robust safety vision.

Hazard Identification and Risk Analysis (HIRA)

Gain insights into various hazard identification techniques (HAZOP, LOPA, etc.) and risk assessment tools that help you systematically evaluate potential risks and their impacts on operations.

Corrective Actions and Positive Reinforcement

Develop the ability to implement corrective actions and reward safe behaviors, creating an environment where safety is a shared value.

Managing Risk and Process Control

This section focuses on risk mitigation strategies and control mechanisms, such as safety instrumented systems (SIS), emergency response planning, and safe operating limits (SOLs).

Operational Discipline and Incident Investigation

Learn how to promote operational discipline within your teams to prevent process safety incidents. This includes techniques for root cause analysis and strategies for investigating near misses and process safety events.

Continuous Improvement in Process Safety

Discover how to establish and maintain a culture of continuous process safety improvement, including the role of audits, performance metrics, and lessons learned from incidents.

Why Invest in RBPS? Case Study

Implementing Risk-Based Process Safety goes beyond mere compliance—it’s about building a sustainable safety management system that reduces risk and enhances operational performance. By training your staff in RBPS, you ensure that safety is integrated into every aspect of your process operations, from day-to-day activities to long-term strategic planning.

Proactively manage process risks

Achieve operational excellence at workplace

Strengthen your organization’s commitment to safety

Take the Next Step Toward Safer Operations

Ensure the safety and success of your operations with our Risk-Based Process Safety Training Program. Contact us today to learn more or to schedule a consultation with our expert trainers.